Vertical Conveyor

for Small Products

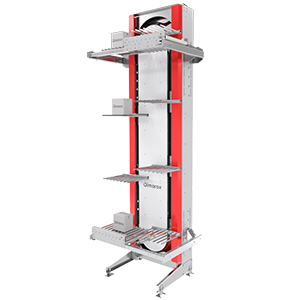

Vertical conveyor Prorunner mk1 -

Space-saving

The Prorunner mk1 is a space-saving discontinuous vertical conveyor that excels in durability and requires minimal maintenance. Its steel structure remains extremely stable under all conditions.

The Prorunner mk1 operates completely silently using a flat belt. Moreover, this type of flat belt requires almost no maintenance. Compared to chain-driven systems, there’s no longer a need for lubrication and tensioning. Thanks to its small footprint, the machine can be used in almost any factory layout.

Efficient Vertical Transport (Vertical Conveyor)

The elevator can easily lift boxes, trays, crates, cases, cartons, or bags weighing up to 100 kg. The Prorunner mk1 is ideal for applications requiring a maximum capacity of approximately 360 movements per hour. Its compact design makes it a space-saving vertical conveyor.

All of this together makes the Prorunner mk1 an extremely efficient and economical solution for your vertical transport needs.

PR2

Built upon the success of the Prorunner mk1, the Prorunner PR2 represents Qimarox’s latest innovation in vertical conveyors. Designed for superior efficiency and reliability, the PR2 features a continuous timing belt pulley system that provides smoother, faster, and more consistent movement compared to the Prorunner mk1.

Additionally, other significant advantages include minimal noise levels, small footprint, and low maintenance requirements. Unlike chain-driven solutions, the Prorunner PR2 doesn’t require lubrication or tension adjustment. Moreover, its compact footprint allows it to seamlessly fit into any type of factory layout.

Vertical conveyor Prorunner PR2

Efficient Positioning

As a result of the continuous toothed belt pulley system, the Prorunner PR2 can move faster. When multiple stop positions are required, the gear motor is equipped with an encoder to ensure accurate positioning.

Even Stronger

The Prorunner PR2 vertical conveyor can transport boxes, trays, crates, or bags weighing up to 100 kg, making it suitable for multiple industries and applications. Thanks to its drive system, this vertical conveyor can achieve higher vertical speeds of up to 2 m/s compared to the PRmk1. The Prorunner PR2 can operate up to approximately 400 cycles per hour. Its compact design ensures an efficient and space-saving solution with a small footprint.

Customizable Options

The Prorunner PR2 offers the same advantages as all our other vertical conveyors:

- Flexible entry and exit: Can be adapted to your specific operational requirements.

- Modular configuration: Easy integration with existing systems.

Why Choose the Prorunner PR2 Vertical Conveyor?

In summary, Qimarox’s commitment to quality and innovation is clearly reflected in the Prorunner PR2. This model not only enhances performance but also offers an economical and robust solution for your VRC needs. The PR2 operates at higher speeds compared to the PRmk1 and accommodates multiple stop positions, making it a superior choice.

Elevate your production efficiency with the Prorunner PR2. Please contact us for more information or a price quote.

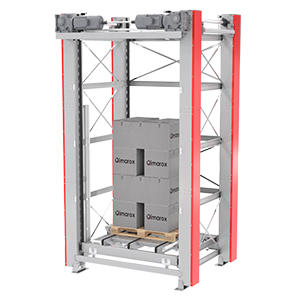

Prorunner PR12 (Vertical conveyor for products up to AMR and pallet size)

A timeless vertical conveyor with a small footprint, superior in positioning accuracy, robustness, and high capacity. This makes the machine an excellent choice for automation transfers.

A separately driven secondary carrier can be attached to the machine column. A roller conveyor or a platform for AGVs, AMRs, or products can be attached to each carrier. The PR12 vertical conveyor transports AGVs (Automated Guided Vehicles), AMRs (Autonomous Mobile Robots), or products to different levels of your facility.

An AGV or AMR adds more flexibility to your daily operations and can reduce labor costs in your operation in many ways. An even higher level of flexibility can be achieved with the new PR12 vertical conveyor, as this versatile lifter enables an AGV or AMR to be transported vertically and operate at multiple different mezzanine levels. The PR12 is designed to use minimal floor space and can be equipped with one or two platforms. Optionally, it’s also possible to replace a platform with a roller conveyor. By using a servo drive, the unit can be easily integrated into demanding, dynamic, and challenging system designs.

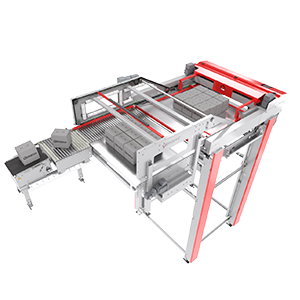

Prorunner mk5 - Modular Continuous Vertical Conveyor

The vertical conveyor Prorunner mk5 is a product with a surprisingly low price tag for a continuously rotating conveyor. The modular-based Prorunner mk5 easily handles up to 2,000 products per hour and is ideal for fast operations. The modular structure of our vertical conveyors enables reduced shipping volumes and lower shipping costs. Our Prorunner mk5 can be used to effortlessly and quickly transport a wide variety of products to a second or higher floor and back to the ground floor.

This energy-efficient product elevator can be used to transport a wide variety of products effortlessly and quickly. Products such as boxes, crates, trays, or bags can be transported to and from any desired height. The product is always transported in an upright position without the risk of product deformation.

Vertical product conveyor

But the Prorunner mk5 can do even more! The elevator system can even be used for both ascending and descending product flows simultaneously. This versatile vertical conveyor is also suitable for use as a vertical sorter by adding retractable conveyors. You can find more information about vertical sorting here.

In addition to the vertical sorting features, a washdown version of the vertical conveyor is also available. This version offers greater durability and is easier to clean, making it ideal for industries requiring clean operations.

Prorunner mk5-WD - Modular continuous vertical conveyor

The washdown vertical conveyor Prorunner mk5 is a fully stainless steel machine specifically designed for harsh environments or situations requiring thorough cleaning of the unit. Designed for enhanced durability and easy cleaning, this product combines efficiency and versatility, making it perfect for sectors requiring clean operations.

Easy-to-clean continuous vertical conveyor

The vertical conveyor Prorunner mk5-WD is a continuous product lifting system based on the standard Prorunner mk5. Like the standard Prorunner mk5, the Washdown version features a modular design that ensures seamless integration and adaptability. With a capacity to handle up to 1400 products per hour, this versatile vertical conveyor is ideal for a wide range of material handling applications. The modular structure of all our vertical conveyors reduces shipping volumes and costs. Whether you need to transport boxes, crates, trays, or bags, this vertical conveyor can handle them all with ease. It can transport products up to a maximum height of 8 meters (26 feet), from the ground floor to upper floors or vice versa. The product is always transported in an upright position without the risk of product deformation. Designed to minimize energy consumption, the Prorunner mk5-WD helps you save on operating costs while maintaining the highest performance.

Washdown vertical conveyor – Are you interested in the Prorunner mk5 or another vertical transport solution?

If you would like more information about our vertical conveyor solutions, you can request a sales inquiry without any obligation. If you have any other questions, please don’t hesitate to contact us!

Continuous vertical conveyor - Prorunner mk5-XL

The Prorunner mk5-XL is designed for use when you want to lift larger products than the normal Prorunner mk5 can handle. This continuous product elevator is still modular-based and offers a maximum capacity of 2,000 products per hour. Overall, the modular structure of our vertical conveyors offers another advantage in that shipping volumes are smaller and therefore shipping costs are cheaper. Our continuous vertical conveyor Prorunner mk5-XL is used to effortlessly and quickly transport a wide variety of (larger) products vertically.

The Prorunner mk5-XL is also an energy-efficient product elevator that can be used to quickly transport products up or down. It is also possible to transport one group of products upwards while simultaneously lowering another group. Products such as boxes, crates, trays, or bags can be transported up to a height of 17.3 meters / 56 ft 10 inches. Products are always transported in an upright position, so there is no risk of product deformation.

Continuous vertical conveyor

Continuous vertical conveyor PRmk5-XL

The Prorunner mk5-XL has the capacity to lift larger products! As mentioned above, our continuous vertical conveyor can be used for both ascending and descending product flows simultaneously! This versatile vertical conveyor is even suitable to function as a vertical sorter by adding retractable conveyors to the input and output. You can find more here.

Are You Ready for Transformation in Your Warehouse?

Contact us to take your warehouse operations to the next level.