Pallet Automation

Systems

Achieve Space and Cost Savings

with Automatic Pallet Storage Systems

Reduce your costs, increase your storage efficiency, and multiply your profits with a customized AS-RS solution for your business!

Automated storage and retrieval systems are systems that enable automatic stocking and retrieval of pallets, baskets, cartons, and boxes in factory warehouses, finished product warehouses, and distribution centers. Many different advantages are obtained by storing in the narrowest and highest areas thanks to vertical robots working between high-altitude racks – from 8 meters to 40 meters. The entire system is managed by ILA IWS software. Regardless of the ERP or WMS system you use, it is possible to provide full and instant integration.

The concept of automated storage is ideal for the following applications and industries:

- All manufacturing industries

- E-Commerce warehouses

- Distribution centers

- Retail warehouses

Features of Stacker Crane System

- Unmanned operation

- Energy efficiency

- High speed and acceleration

- Simple and compact design

- Quick return on investment (ROI)

- Long service life (+20 years)

- Local service and maintenance support

Advantages of Stacker Crane System

Space and Cost Savings

- Up to 70% space savings due to volume utilization

- Maximum work with minimum operators thanks to unmanned (dark warehouses)

- Maximum pallet layers due to minimum distance between two stacked pallets

- Up to 60 “% aisle savings thanks to narrow 1600 mm robot corridor”

Fast Shipment

- Even when you’re not working, your robots work to prepare all pallets that need to be shipped and make them ready for shipment on conveyor lines

- In Double Deep storage systems, 30-40 double-cycle movements per hour, 60-80 single-sided movements per hour (should be calculated specifically for your project each time based on FEM standards, warehouse and product structure)

Guaranteed Error-Free Picking

As long as the correct pallet barcode is used, your pallet won’t get lost in the warehouse.

Whichever product you want to retrieve, 100% that product comes to the workstation.

Full Integration with ERP and WMS Systems

- Provides 100% stock control thanks to ILA IWS software

- Regardless of the software you use, the system working with work order logic processes orders received from your ERP “and reports back the final order and stock status to the ERP”.

- Quick training process and uninterrupted communication thanks to user-friendly screens

Modular Hardware

You can plan the expansion of your warehouse according to your needs.

You can build all your racks and adapt additional robots to the system as your business grows

Flexibility

- Don’t be limited to Euro (800x1200mm) and Industrial (1100x1200mm) pallets, ILA has special solutions for your pallets of any size.

- Either ‘Double Deep’ or ‘Multi Deep’ or both can be planned together. The most accurate and efficient solution based on your SKU and Order structure is at ILA.

Temperature-Controlled Environments

Full automation in cold storage warehouses

Modular solutions specific to different temperature norms such as +4 / 0 degrees / -18 / -22 / -24

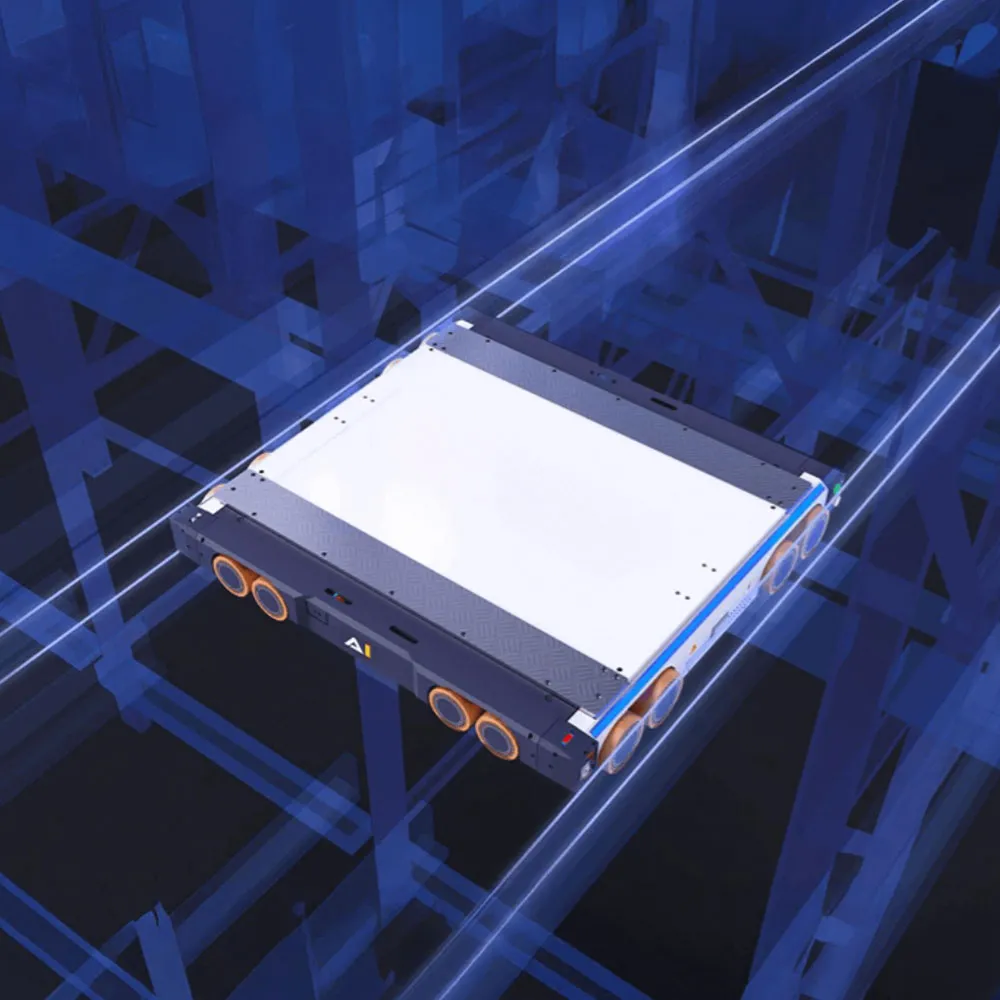

Pallet Shuttle Systems

Imagine an operation where efficiency is not just a goal but a standard, where human effort is optimized, and damage and waste are virtually eliminated. Envision a system that maximizes every square meter of your facility, brings your products to market with unparalleled speed, and ensures flawless sequencing and order fulfillment. With the 4-Way Shuttle ASRS robot, you get a solution that’s not only highly flexible and scalable but also equipped with built-in redundancy, ensuring your operations remain adaptable and responsive to business needs or challenges. Experience the peace of mind that comes with high uptime, seamless lifecycle management, and inventory control so accurate it’s nearly effortless. It’s a revolution in how you manage your operations, delivering unmatched efficiency, reliability, and success.

Why 4-Way Shuttle:

- Flawless Sequencing and Order Fulfillment

- Flexibility, Scalability, and Redundancy

- Accurate Inventory Management

- High Visibility

- Highest Storage Density per Square Meter

- High Uptime and Lifecycle Management

The 4-Way Shuttle, like all ILA ASRS systems, ensures that machines and pallets are always positioned in an absolute, precise, and reliable manner. The system, which has a detailed map of the entire warehouse, ensures that machines move accurately and smoothly, enabling optimal storage of goods. With the 4-way Shuttle and compact pallet positioning, you maximize the existing storage space.

Are You Ready for Transformation in Your Warehouse?

Contact us to take your warehouse operations to the next level.