Palletizing Machine

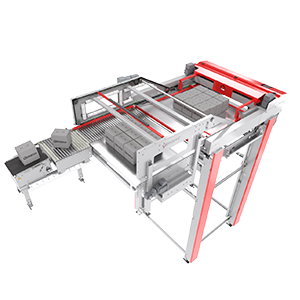

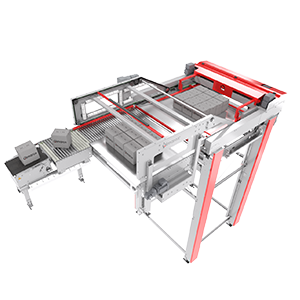

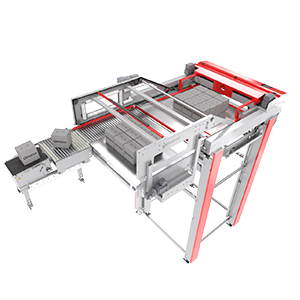

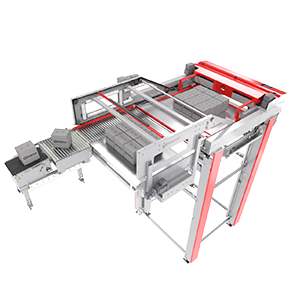

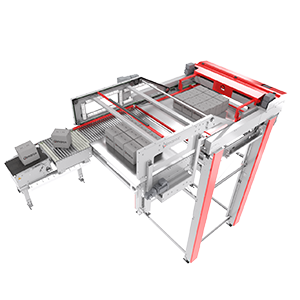

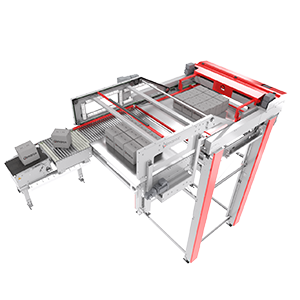

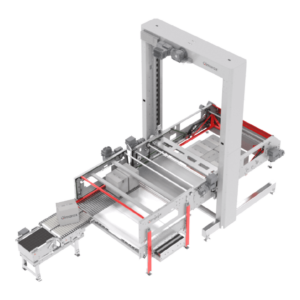

Highrunner HR9: Automatic Layer Pattern Selection

The Qimarox Highrunner HR9 Logistics palletizer is specifically designed for logistics operations. As a result, this machine is highly effective in areas where many different products are processed in short batches. Our unique and patented layer formation system can create a wide variety of layer patterns. These patterns can be automatically selected or generated by the state-of-the-art pattern generator. A specially designed pattern generator will provide you with the most suitable layer pattern based on box size and pallet size. For example, if the setup is equipped with a full 3D product scanner, it is even possible for the system to operate completely autonomously.

Because the pattern formation system is at a high level and the pallet moves up and down with the pallet elevator (Qimarox Prorunner mk10), higher efficiency can be achieved. As a result, the top of the pallet is always at the same level as the pattern formation conveyor. Consequently, higher layer capacity is possible as the stacking plates can quickly pick up a new layer after a layer has been placed on the pallet.

Logistics Palletizer HR9

Layer by Layer

The Highrunner HR9 Logistics palletizer is based on the Highrunner HR7. This machine is the fastest and most flexible palletizer in the Qimarox series. Interestingly, products are placed on the pallet layer by layer with this machine. To do this, the machine has a built-in buffer where each row created remains until a layer is completed. The Highrunner HR9 has to make fewer movements by placing the entire layer at once. This saves time, increasing capacity.

Since the pallet moves up and down with the Prorunner mk10 vertical pallet conveyor, layers no longer need to be moved up and down while being stored. As a result, time is saved, especially for pallets that need to be stacked 1.80 meters or higher. This makes the Highrunner HR9 one of the fastest palletizers on the market.

Feeding Pallets In and Out

When a pallet is full, the pallet elevator moves all the way down so it can be transported via a pallet handling system. At the same time, an empty pallet can be supplied from the opposite direction.

Highrunner HR10: Palletizer for the Beverage Industry

In the beverage industry, there are various challenges you need to address if you want to automate the palletizing process.

The Qimarox HR10 Palletizer for the beverage industry is designed to cope with the overall efficiency of a production line, which is the main issue in this industry. This required efficiency exceeds the needs of many other industries. The Qimarox HR10 palletizer can achieve high output combined with high flexibility by using the advantages of a top-level infeed machine based on the Highrunner HR7. Additionally, the layer weight can be much higher compared to other industries. The layer transport system of this palletizer can handle layer weights up to 280 kg.

The changeover of empty pallets and loaded pallets over time is minimized by having a buffer position for an empty pallet right in front of the loading position. As soon as a loaded pallet exits the system, an empty pallet is moved into position. While moving upwards, the empty pallet is centered and aligned to receive the first layer. The unique layer formation allows for high-speed production of a layer. By adding a buffer position for a complete layer, the layer formation will not stop during pallet changeover.

Limited Floor Space

Many factories focus on production first, and end-of-line automation is often only considered after everything is set up and production is running smoothly. Palletizing is often done manually, and when end-of-line automation begins, only limited floor space is available. When using a high-level infeed palletizer, the only floor space used is the actual loading position. The layer formation is placed on a mezzanine and does not interfere with the packaging line.

Product Fragility

In the beverage industry, the product being handled can be very fragile (e.g., glass). With Qimarox’s unique layer formation, each product is moved with very gentle pushing movements, ensuring there is no risk of damaging the product. Every movement is powered by an electric geared motor equipped with a frequency inverter and encoder. This feature allows all speeds, acceleration, deceleration, etc., to be stored within recipe data.

Maintenance and Downtime

Every module used in the Highrunner HR10 palletizer is designed to minimize maintenance requirements. Because the basic design is made with standard mechanical parts that can be replaced very quickly when necessary, most mechanics can keep the machine running. Downtime is very low since the layer formation principle is very precise and there is almost no risk of failure. In a situation where the machine is stopped, the operator can quickly restore the machine’s operation. The HMI (Operator panel) will show the malfunction and also which action to perform to restore production.

Transform Your Beverage Production with Automatic Palletizing

Being ahead in the fast-paced beverage industry means embracing efficiency and innovation. Automating your palletizing process offers a range of attractive advantages that can transform your operations:

- Increase Efficiency: Experience faster palletizing, increase your work volume and production rates.

- Ensure Consistency: Achieve uniformity with precise placement and stacking, reduce errors, and enhance product quality.

- Save on Labor Costs: Reduce manual labor by automating repetitive tasks and allow your workforce to focus on more skilled roles.

- Enhance Workplace Safety: Create a safer working environment by minimizing injury risks associated with heavy lifting and repetitive movements.

- Maximize Space Utilization: Optimize your facility layout with efficient automated systems designed for limited spaces.

- Scale with Ease: Provide flexibility in your production capacity to quickly adapt to changing demands and seasonal variations.

- Improve Quality Control: Integrate quality checks into your palletizing process to ensure only the best products reach the market.

- Leverage Data Insights: Collect and analyze production data to ensure continuous improvement and increase operational efficiency.

- Reduce Product Damage: Minimize handling, especially for fragile containers, and lower breakage rates to preserve your profitability.

- Support Sustainability: Optimize shipping loads to reduce transportation costs and emissions, aligning with your sustainability goals.

- Gain Competitive Edge: Respond quickly to market demands and differentiate your business from competitors by increasing efficiency.

- Ensure Compliance and Traceability: Stay compliant with industry regulations while enhancing product traceability throughout your supply chain.

Embrace automation in your palletizing process today and unlock the potential for significant operational improvements, cost savings, and a stronger competitive position in the beverage industry. Transform your production; contact us to learn more!

Highrunner HR11: Palletizer for Canned Foods

The Qimarox Highrunner HR11 palletizer is specifically designed to automate the palletizing process in the canned food industry. In this sector, efficiency, consistency, and safety are crucial. The specialized Highrunner HR11 palletizer is engineered to meet these needs and more, providing a range of benefits that enhance your production process. Whether foods are packaged in tin cans or glass, the HR10 can handle both. In most cases, cans or jars are grouped on a tray with or without film, and here too, the HR10 can process both.

Palletizing can help improve the canned food producer’s processes by increasing efficiency, protecting canned products, enhancing storage capabilities, reducing manual labor along with injury risks, and generally improving safety for employees.

Why Use a Palletizer for Canned Foods?

The transition from manual to automatic palletizing has many benefits, including reducing manual labor costs, eliminating the possibility of inconsistency and errors that can lead to product damage during shipping and complicate inventory management. It also reduces safety risks, as repetitive heavy lifting and awkward postures are known to increase the risk of workplace injuries, making safety a significant concern.

Layer by Layer

The Highrunner HR11 Palletizer for Canned Foods is based on the Highrunner HR7. This machine is the fastest and most flexible palletizer in the Qimarox series. Interestingly, products are placed on the pallet layer by layer with this machine. To do this, the machine has a built-in buffer where each row created remains until a layer is complete. The Highrunner HR11 has to make fewer movements by placing the entire layer at once. This saves time, increasing capacity.

Because the pallet moves up and down with the Prorunner mk10 vertical pallet conveyor, the layers no longer need to be moved up and down when being stored, as it is the pallet that can move up and down relative to the Prorunner. As a result, time is saved, especially with pallets that need to be stacked 1.80 meters or higher.

Feeding Pallets In and Out

As soon as a pallet is loaded with all layers, the pallet elevator lowers the pallet completely so it can be transported via a pallet handling system. To maximize process efficiency, an empty pallet can be supplied simultaneously from the opposite direction. The empty pallet will be centered at the loading position and will move upwards to receive the first layer.

Why Should You Choose to Automate the Palletizing Process?

Investing in a palletizer for cans or jars is a strategic move that increases productivity. It also reduces costs and ensures first-class quality and safety. Automate your palletizing process with us and position your production line for long-term success in the competitive canned food market.

Are you ready to transform your operations? Contact us for more information or to request a quote.

HR12 Highrunner Palletizer for PET / HDPE Bottles (Non-Food)

In industries processing PET and HDPE bottles, efficient palletizing solutions are essential for smooth production processes. The Qimarox HR12 Palletizer for PET / HDPE Bottles is designed to meet these specific needs with precision and reliability. This innovative machine provides optimal palletizing for non-food PET/HDPE bottles and offers a unique combination of flexibility and capacity compared to traditional and robotic palletizers, allowing customizable rotation options of 0°, +90°, -90°, and 180° (also possible for larger products).

Why is the HR12 Palletizer Ideal for the PET / HDPE Bottling Industry?

- Increased Efficiency

The HR12 palletizer significantly speeds up bottle handling and pallet loading processes, reducing overall production time. With a fully automated system, you can minimize manual labor, resulting in lower operating costs and faster return on investment.

- Versatile Layer Formation

What sets the HR12 apart is its ability to create precise bottle layers with adjustable rotation angles, ensuring optimal stability during transportation. This is crucial for the non-food bottling industry, where bottles of irregular shapes and sizes can pose challenges. The HR12 can handle them all with precision.

- Optimized Floor Space

The compact design of the HR12 allows for installation near other machines such as bottling lines or case packers. This saves valuable floor space and simplifies production line layouts, especially in facilities where space is limited.

- Pre-Programmed Patterns

The HR12 comes with pre-loaded layer patterns specifically for PET and HDPE bottles, offering flexibility and ease of use. Using the intuitive Qimarox Pattern Generator, operators can adjust or create new patterns by simply entering product and pallet dimensions. This user-friendly interface eliminates the need for specialized training.

- High-Speed Layer-by-Layer Palletizing

The HR12 maximizes efficiency by placing an entire layer of bottles at once. Requiring fewer movements compared to traditional palletizers means the HR12 can easily handle high volumes. The machine’s capacity is further enhanced by its ability to lift pallets via the Prorunner mk10 vertical conveyor, eliminating unnecessary bottle lifting during stacking.

- Continuous Pallet Flow

The HR12 palletizer ensures smooth feeding of pallets in and out. While one pallet is being filled, the system simultaneously removes the completed pallet and brings in an empty one. This uninterrupted flow reduces the time required for pallet changes, increasing overall efficiency, Overall Equipment Effectiveness, and minimizing downtime.

Built for the Future of Bottling

The Qimarox HR12 Highrunner palletizer is designed to overcome the unique challenges of the PET and HDPE bottling industry. Whether you need to rotate bottles for optimal stacking or process various shapes and sizes, the HR12 offers a robust, flexible, and high-speed solution that enhances both efficiency and cost-effectiveness.

Benefits of the Highrunner HR12

- Specially designed for the PET / HDPE Bottles (non-food) industry based on many reference projects

- Unique pattern creation method where products are positioned according to exact coordinates (patented)

- Includes automatic pop-up safety vertical pallet conveyor Prorunner PR10

- Built-in buffer for accumulating products in layers

- User-friendly touchscreen operation

- Pattern generator included

- Freely programmable stacking patterns

- Robust construction with excellent finish for demanding jobs

- Easy access for service and maintenance

- Small footprint

- Customizable rotation options of 0°, +90°, -90°, and 180° (also possible for larger products)

- Standard machine with components available on the market

Transform Your Production Today!

Investing in the Qimarox HR15 Palletizer will unlock significant operational improvements, cost savings, and competitive advantage in the beverage market. Don’t hesitate to reach out to us for more information or to discuss your palletizing needs!

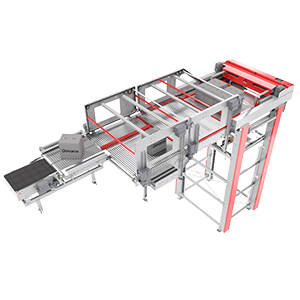

Highrunner HR15: Palletizer for beverage cartons

Maximize Palletizing Efficiency with Qimarox HR15 Palletizer for Beverage Cartons

Automating the palletizing process presents unique challenges. High throughput, precision, and flexibility are essential to meet the demands of modern production lines. This is where the Qimarox Highrunner HR15 Palletizer for beverage cartons comes in – an advanced solution designed to optimize performance in high-demand environments.

The Qimarox HR15 Palletizer is specifically designed to address the complexities of palletizing in the beverage industry. Building on the successful design of the Highrunner HR7, the HR15 with its high-level infeed features offers both high throughput and flexibility. The HR15 palletizer is ideal for palletizing systems for beverage carton products such as TetraPak and Combibloc. The HR15 layer palletizer comes with all industry-known layer patterns pre-programmed. These patterns can be automatically selected without any manual adjustments.

High Throughput with Superior Flexibility

The HR15 can handle layer weights up to 180 kg. The Qimarox palletizer is flexible and also very suitable for applications where carton sizes and weights vary. The intelligent layer handling system is designed to create and manage high-speed layers seamlessly, ensuring continuous operation even during pallet changes.

Seamless Changeover for Maximum Uptime

One of the standout features of the HR15 is its efficient pallet exchange system. The transition between empty and loaded pallets is streamlined to minimize downtime. The HR15 uses a buffer position for an empty pallet immediately in front of the loading position. As soon as the loaded pallet moves out, the empty pallet automatically aligns and centers itself, ready to receive the next layer. This unique layer formation system ensures that the palletizing process continues smoothly without interruption during pallet changes.

Limited Floor Space? No Problem with HR15

Many beverage factories prioritize production first and only consider end-of-line automation after their systems are running smoothly. However, by this time, floor space is often limited. The high-level infeed design of the HR15 ensures that only the space required for the actual loading position is used, leaving the rest of the floor clear. This system can be easily integrated into existing production lines without requiring extensive modifications. By placing the layer formation on a mezzanine, valuable floor space is freed up and bottlenecks in the packaging line are prevented.

Handle Fragile Beverage Cartons with Precision

In the beverage industry, automation needs to be gentle yet precise, especially when handling cartons. The HR15’s unique layer formation system ensures smooth and controlled handling of each product. Thanks to its electric gear motors equipped with frequency inverters and encoders, the HR15 can precisely control speeds, acceleration, and deceleration. These parameters are stored in the machine’s recipe data, allowing for quick adjustments for different carton types and sizes, minimizing the risk of damage and ensuring safe handling of fragile cartons like TetraPak, Combibloc, etc.

Minimize Downtime and Maintenance

The HR15 Palletizer for beverage cartons is designed to maximize uptime and minimize the need for extensive maintenance. Its modular structure and use of standard mechanical parts make system maintenance quick and easy, reducing the risk of costly downtimes. In the rare event of an issue, the HMI (Human-Machine Interface) displays clear error messages and suggests corrective actions to get the system back up and running quickly. The layer formation mechanism is designed to be extremely precise, reducing the risk of interruptions and ensuring smooth, continuous operation.

Key Benefits of the Qimarox HR15 Palletizer for the Beverage Industry:

- High throughput capacity adapted for fast-paced beverage production lines.

- Handles layer weights up to 180 kg, common in beverage carton packaging.

- Efficient changeover process with minimal downtime for both empty and loaded pallets.

- Flexible design adapting to various carton sizes and formats.

- Intelligent layer formation system for uninterrupted and continuous operation due to the layer formation shape.

- Optimized for Limited Space: High-level infeed ensures minimal floor space usage, freeing up valuable production area.

- Designed for Fragile Products: Precise control mechanisms minimize the risk of damage to delicate cartons, ensuring a high Overall Equipment Effectiveness for the production process.

- Low Maintenance and Downtime: Built with durability in mind, the HR15 requires minimal maintenance, reducing downtime and ensuring your production line runs smoothly.

- Scalable Solution: Easily adapt to changing production needs, whether you’re scaling up or dealing with seasonal demand fluctuations.

- Reduce Labor Costs: Automating the palletizing process lowers labor costs and reduces human errors, providing long-term savings.

Highrunner HR17: Palletizer for Fresh Food (such as fruits and vegetables)

The Qimarox Highrunner HR17 palletizer is specially designed for the Fresh Food Production industry. In the Fresh Food products industry, handling delicate items like fruits and vegetables presents unique challenges. Traditional manual processes can lead to spoilage, damage, and inconsistency, ultimately affecting product quality and shelf life. To prevent this, the specialized Highrunner HR17 palletizer steps in, offering advantages tailored to meet your specific needs. The palletizer is designed to minimize the risk of product damage and improve the end-of-line process, reducing costs and optimizing cycles.

Why should you choose our palletizer for fresh food products?

Manual handling of fresh food products brings a range of challenges, including inconsistent quality, high labor costs, and increased risk of contamination. Our palletizer overcomes these issues by providing a reliable, efficient, and hygienic solution, ensuring your operations run more smoothly and efficiently. The palletizer efficiently stacks boxes or trays of fruits and vegetables onto a pallet layer by layer.

Layer-by-layer palletizing

As with all our Highrunner palletizers, the foundation is laid with the Highrunner HR7. Highrunner palletizers can place products onto the pallet layer by layer, thanks to an internal buffer where products are positioned and accumulated until a layer is complete. The Highrunner HR17 minimizes the number of movements required by placing all layers at once, saving time and increasing efficiency.

Another advantage of the Highrunner HR17 is that the pallet itself moves up and down to receive another layer, rather than the layers. This design choice is particularly beneficial as it saves even more time when stacking pallets 1.80 meters or higher. As a result, the Highrunner HR17 is one of the fastest palletizers on the market. When a pallet is full, the pallet elevator moves completely down so it can be transported via a pallet handling system. At the same time, an empty pallet can be supplied from the opposite direction.

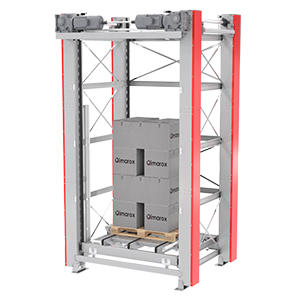

Palletizer Highrunner HR7: rapid layer placement

The most important feature that distinguishes the Highrunner flexible palletizer from other palletizing systems is the position of the pattern-forming conveyor. In Highrunners, the pattern-forming conveyor is located high up, while the pallet is moved up and down with a pallet lifter. As a result, the top of the pallet is always at the same level as the pattern-forming conveyor. *NOTE: Delivery time is subject to agreement*

Layer-by-layer palletizing

The Highrunner HR7 is the fastest and most flexible palletizer in the Qimarox series. Interestingly, with the Highrunner HR7, products are placed onto the pallet layer by layer. To do this, the machine has a built-in buffer where each row formed remains until a layer is completed. By placing the entire layer at once, the Highrunner HR7 needs to make fewer movements. This saves time, increasing capacity.

With the Highrunner HR7 flexible palletizer, it’s the pallet that moves up and down, so the rows no longer need to be moved up and down while being stored. This saves even more time, especially for pallets that need to be stacked 1.80 meters or higher. This makes the Highrunner HR7 one of the fastest palletizers on the market.

Feeding pallets in and out

When a pallet is full, the pallet elevator moves completely down so it can be transported via a pallet handling system. At the same time, an empty pallet can also be supplied from the opposite direction.

The Highrunner HR7 can handle a wide range of products:

- Boxes

- Boxes with lids

- Trays

- Trays with foil

- Buckets

- CRATES

- Jerrycans etc.

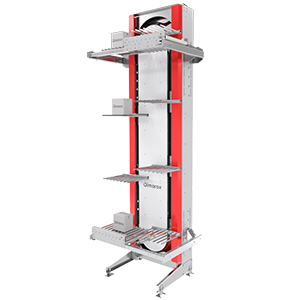

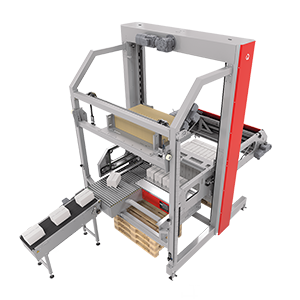

Qimarox's modular LOWRUNNER LR1 palletizer

is a 5-axis palletizer with a capacity of up to 800 packages per hour. It’s an entry-level model suitable for an environment where a quick return on investment is desired or necessary. Optionally, the LOWRUNNER LR1 can also place pallets and interlayer sheets by itself. *NOTE: Delivery time to be discussed*

Palletizer movements

Low-level infeed

With the Lowrunner LR1, there is no need for an operator platform as the entire layer formation station is placed at ground level. The unique Qimarox layer formation station can position each product in an exact location. This is done with a product pusher that places each product in a product row. When a row is completed, it is placed on the stacking plate. This is a unique feature as most low-level palletizers process products layer by layer. By placing products row by row on the pallet, the machine’s floor space can be minimized.

A stable pallet load is guaranteed by pulling the stacking plate in two directions, to the front and back of the pallet. Thanks to this solution, the Lowrunner LR1 palletizer is very suitable for a wide variety of products.

Pallet Handling

As an add-on, it is possible to handle empty pallets without adding additional system components or requiring more floor space. A stack of empty pallets is placed under the layer formation station and can be picked up by the stacking plate. This functionality is normally only known in robotic palletizing solutions.

Handling of Interlayer Sheets

The same system used for picking up and placing empty pallets can also be used to place interlayer sheets between layers. Interlayer sheets can be used to increase the load stability of a pallet. When used with the row placing feature of Qimarox’s Lowrunner LR1 modular palletizer, fewer interlayer sheets are needed. This is because the outer parts of the cartons are always perfectly stacked on top of each other, thus utilizing the maximum strength of the carton.

The Lowrunner LR1 can handle a wide range of products:

- Boxes

- Lidded boxes

- Trays

- Trays with foil

- Buckets

- CRATES

- Jerrycans etc.

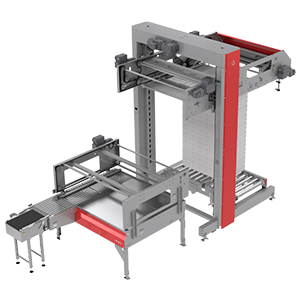

Palletizer Lowrunner LR3

Flexible Palletizing

Qimarox’s modular LOWRUNNER LR3 palletizer is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where a quick return on investment is desired or required. Optionally, the LOWRUNNER LR3 can also be equipped with the Qimarox Sheetrunner to place interlayer sheets between layers.

Qimarox’s modular palletizer Lowrunner LR3 is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where a quick return on investment is desired or required. Optionally, the Lowrunner LR3 can also be equipped with the Qimarox Sheetrunner to place interlayer sheets between layers. *NOTE: Delivery time to be discussed*

Low-Level Infeed

With the Lowrunner LR3, there is no need for an operator platform as the entire layer formation station is placed at ground level. The unique Qimarox layer formation station can position each product in an exact location. This is done with a product pusher that places each product in a product row. When a layer is completed, it is placed on the bi-directional stacking plate. This is a unique feature as most low-level palletizers process layers with a single-directional stacking plate. When using a bi-directional stacking plate to place layers on the pallet, the outer line of the pallet will be very consistent to get maximum strength from a cardboard box, and a stable pallet load is guaranteed. Thanks to this solution, the Lowrunner LR3 palletizer is very suitable for a wide variety of products.

The Lowrunner LR3 can handle a wide range of products:

- Boxes

- Lidded boxes

- Trays

- Trays with foil

- CRATES etc.

The Lowrunner is modular in structure. This means that various options are available for each module, depending on customer requirements and the products that require palletizing.

In short, you get the system that best suits your needs. However, this system can be fully adapted to changing conditions in the future, thanks to the interchangeability of its modules.

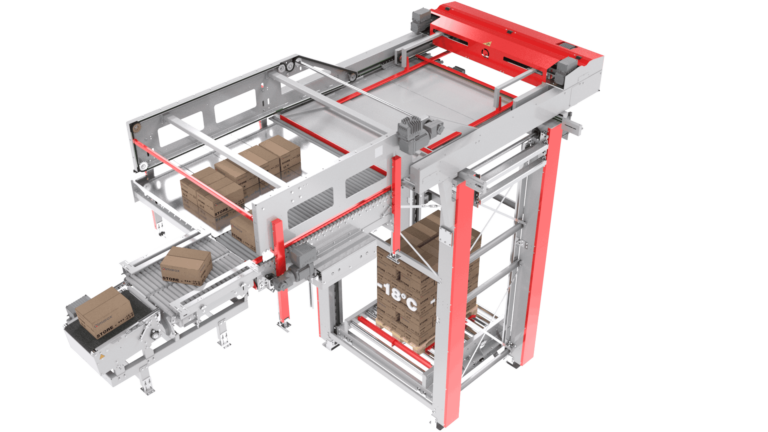

Lowrunner LR8 Palletizer for IQF Products such as Vegetables, Fruits, and French Fries

Palletizing cartons containing IQF (Individually Quick Frozen) products presents unique challenges compared to other industries. Over the past decades, we have proven our ability to provide the best solutions for these challenges.

The LR8 palletizer for IQF products has a special configuration specifically designed to handle cartons that are not completely filled to the top or are overfilled and bulging on both sides. This LR8 layer palletizer comes pre-programmed with all known layer patterns in the industry. These patterns can be automatically selected without the need for manual adjustments, providing efficient and reliable palletizing for frozen foods such as vegetables, French fries, and fruits.

Frozen Food (IQF) Industry

In the frozen food industry, efficient management of food storage and transportation is crucial. This is where palletizers come into play. The Lowrunner LR8 palletizer is a machine designed to efficiently load pallets with frozen food products.

There are several reasons why using a palletizer in the frozen food industry is beneficial. Firstly, it speeds up the loading and unloading process for transport trucks, resulting in shorter shipping times and reduced risk of food thawing. Secondly, using a palletizer helps reduce labor costs by automating a tedious and physical task. Finally, a palletizer can be programmed to load pallets in a way that optimizes storage space, saving on storage fees.

In summary, using a palletizer in the frozen food industry has many advantages, including shorter shipping times, lower labor costs, and optimized storage space.

Low-level feeding

With the Lowrunner LR8, the entire layer formation station is placed at floor level, eliminating the need for an operator platform. The unique Qimarox layer formation station can position each product in an exact location. This is done with a product pusher that places each product into a product row. When a layer is complete, it is placed on the bi-directional stacking plate. This is a unique feature as most low-level palletizers process layers with a unidirectional stacking plate. When using a bi-directional stacking plate to place layers on the pallet, the pallet’s contours will be very consistent to obtain maximum strength from a cardboard box, ensuring a stable pallet load. Thanks to this solution, the Lowrunner LR8 palletizer is highly suitable for a wide variety of products.

The Lowrunner LR8 can handle a wide range of products:

- Boxes

- Lidded boxes

- Trays

- Trays with foil

- CRATES, etc.

The Lowrunner has a modular structure. This means that various options are available for each module, depending on customer requirements and the products requiring palletizing.

In short, you get the system that best suits your needs. However, this system can be fully adapted to changing conditions in the future, thanks to the interchangeability of its modules.

Highrunner HR8

The Highrunner HR8 Palletizer for IQF products such as Vegetables, Fruits, and French Fries. Palletizing cartons containing IQF products comes with many challenges, unlike other industries. Qimarox has proven to offer the best solution to overcome these challenges with its many installations over the past years. With the Highrunner HR8 palletizer for IQF products, we have developed a special configuration focusing on handling cartons that are not completely filled or so full that they bulge on both sides. The HR8 layer palletizer comes with all known layer patterns in the industry pre-programmed. These patterns can be automatically selected without any manual adjustments.

Frozen Food (IQF) Industry

In the frozen food industry, efficient management of food storage and transportation is crucial. Palletizers play a key role here. The Highrunner HR8 Palletizer for IQF products is a machine designed to efficiently load empty pallets with frozen food products.

There are several reasons why using a palletizer in the frozen food industry is beneficial. Firstly, it accelerates the product handling process and the loading and unloading operations for transport trucks. This results in shorter shipping times and a reduced risk of thawed food. Additionally, using a palletizer helps reduce labor costs by automating a tedious and physical task. Finally, a palletizer can be programmed to load pallets in a way that optimizes storage space and saves on storage costs.

Frozen Food (IQF) Industry

In the frozen food industry, efficient management of food storage and transportation is crucial. Palletizers play a key role here. The Highrunner HR8 Palletizer for IQF products is a machine designed to efficiently load empty pallets with frozen food products.

There are several reasons why using a palletizer in the frozen food industry is beneficial. Firstly, it accelerates the product handling process and the loading and unloading operations for transport trucks. This results in shorter shipping times and a reduced risk of thawed food. Additionally, using a palletizer helps reduce labor costs by automating a tedious and physical task. Finally, a palletizer can be programmed to load pallets in a way that optimizes storage space and saves on storage fees.

In summary, using a palletizer in the frozen food industry has many advantages, including shorter shipping times, lower labor costs, and optimized storage space.

Benefits of the Highrunner HR8

- Offers perfectly aligned pallets vertically thanks to double-sided stacking plates.

- Perfect positioning due to motorized layer holders on each side.

- Flexible layer formation in the most challenging installation areas such as elevator shafts and wells.

- Four-sided open design.

- Low cost due to robust design and minimum number of parts.

- Operator-friendly HMI (Human-Machine Interface) with different access levels:

- Ability to use directly through the HMI without requiring additional software engineering.

- User-friendly HMI.

- Easy troubleshooting system with intuitive menus supported by an integrated CCTV.

- Control architecture based on PACKml standards.

- Irregularly shaped boxes, such as those containing frozen vegetables, can be processed thanks to the machine’s mechanical design.

- Layers are stacked flat on top of each other (despite irregularly shaped boxes)

- Due to the compression of the entire layer under each layer.

- Suitable capacity and patterns for the most common case packers in the IQF industry.

- Unique layer formation system

What sets every Qimarox layer palletizer apart from other solutions on the market is the unique way a layer is constructed. Thanks to the patented design, every layer pattern used in the frozen food industry can be created without any manual adjustments.

Since floor space is very expensive, the flexible palletizer’s line feed also allows machines to be placed side by side, so the machine can be aligned with the case packer.

Palletizing frozen vegetable cartons requires a layer formation system that can handle both normal cartons and those that are – usually – bulging due to low carton quality and the characteristics of the packaged natural product. By moving and positioning each row of cartons separately, it is possible to create full gaps between each row. These gaps are used to absorb tolerances on the cartons when the layer is placed on the pallet.

This layer transport method has repeatedly proven to offer the best solution for creating robust and stable pallet loads, even with bulging cartons.

Pattern Generator

Every Highrunner HR8 palletizer for IQF products comes pre-programmed with layer patterns commonly used in the industry. Each layer pattern can be freely adjusted with the HMI, and completely new layer patterns can be created very easily. This can be done with the Qimarox Pattern Generator and can be used without detailed knowledge of the palletizer. You can simply enter the product and pallet dimensions, and the system will show you the most suitable layer patterns to choose from.

Layer-by-layer palletizing

Another advantage is that with the Highrunner HR8, products are placed on the pallet layer by layer. By placing the entire layer at once, the Highrunner HR8 needs to make fewer movements. This saves time, increasing capacity.

Since the pallet moves up and down with the Prorunner mk10 vertical conveyor, mixed products do not need to be collected and moved up and down when being stored. This saves even more time, especially for pallets that need to be stacked 1.80 meters or higher. This makes the Highrunner HR8 one of the fastest palletizers on the market. Using only simple pushing movements without the need to lift products also increases reliability and reduces production line downtime.

Feeding pallets in and out

When a pallet is full, the pallet elevator moves completely down so it can be retrieved via a pallet transport system. At the same time, an empty pallet can be supplied from the opposite direction. This continuous flow of pallets improves the time required for pallet exchange, which is the most time-consuming aspect of any palletizing system and has a significant impact on overall efficiency. Additionally, all Highrunner palletizers have four sides for loaded pallet output and four sides for empty pallet input.

Are You Ready for Transformation in Your Warehouse?

Contact us to take your warehouse operations to the next level.