ACR Systems

New Peak in Storage with Haipick Robots!

Faster, Higher, More Efficient Automation.

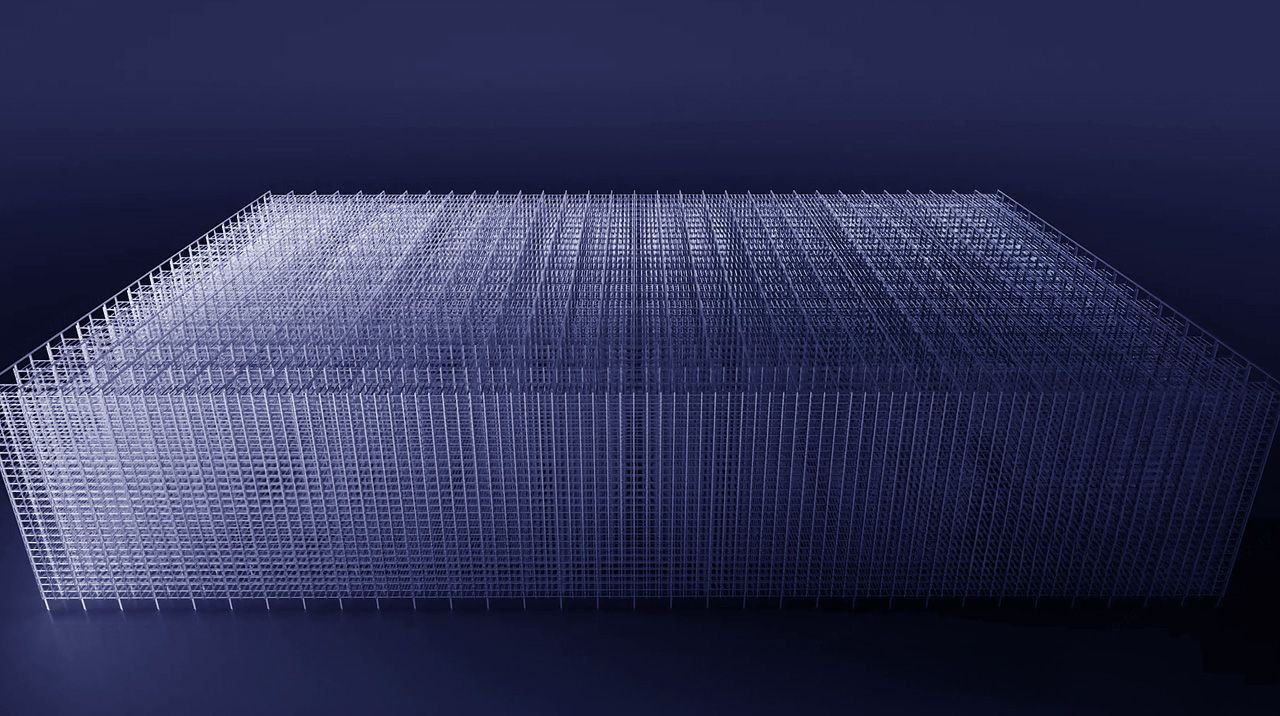

A simplified, high-performance evolution of traditional ASRS, offering superior efficiency and scalability while eliminating cost challenges.

Supported by the HaiClimber robot, the HaiPick Climb system revolutionizes “goods-to-person” warehouse automation with advanced technology in a compact and efficient design. It’s a simplified, high-performance evolution of traditional ASRS, offering superior efficiency and scalability while eliminating cost risks.

HAIPICK A42D Double-deep ACR

Customizable telescopic fork for easy access to two rows using double-deep racking

• Provides 4.5 m picking height, enabling higher storage space

• Increases storage density by 130% while reducing aisle numbers by up to 50% compared to traditional manual warehouses.

• Intelligent optimization algorithm can be customized to fit various business models and optimize stock accessibility

• First successful project implemented in March 2020

HAIPICK A42N Carton-picking ACR

• Suitable for multi-dimensional carton/box picking in multiple sizes.

• Different storage scenarios can be configured.

• Carton boxes can be reused as long as their forms are not damaged

• Operation is possible without DM codes using 3D visual camera technology

• Software platform can be customized to support product picking mode to meet customer needs

• First successful project implemented in March 2020

HAIPICK A42T Telescopic Lift ACR

• Standard robot height of 3.7 m, customizable between 1.5 m-3.7 m

• Ultra-wide storage range, flexibly covering storage ranges from 0.25 m to 6.50 m

• Suitable for irregular and uneven heights in warehouses, with an intelligent lifting system to meet different height requirements

• Sustainable operation, flexible mobility between different floors and fire zones

• Appropriate routing and quick distribution

Intelligent Goods-to-Person Principle

Applicable for all types of boxed and/or packaged product scenarios

Application areas: E-Commerce, 3PL, Retail, Textile, Electronics, Pharmaceuticals, Book logistics and Libraries, etc.

Simplified Efficiency

Simplified Automation

Simplicity and Accelerated Return on Investment

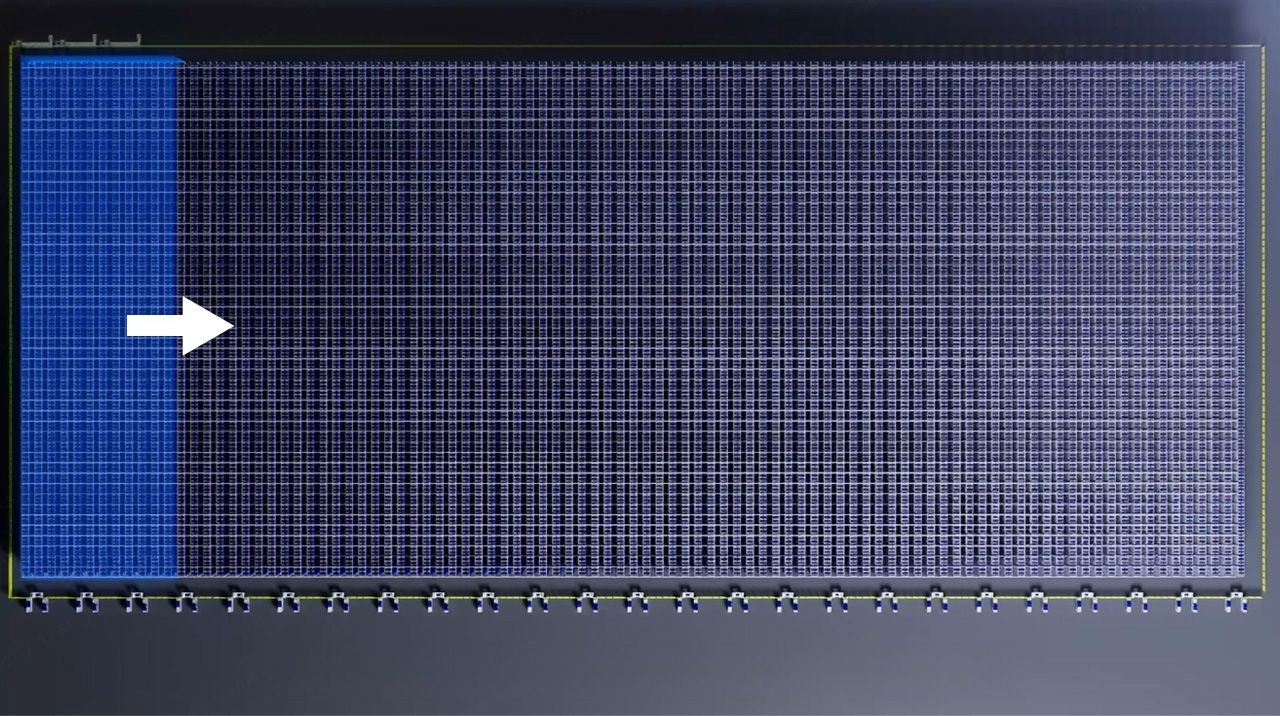

HaiClimber uses two climbing arms to connect to the guide rail on one side of the rack, halving the connection points compared to traditional climbing systems. This reduces maintenance, provides more reliability, and simplifies installation by reducing precision requirements for racks and floors, enabling rapid deployment. As a result, HaiPick Climb is ideal for renovating existing warehouses or excellence in newly constructed facilities.

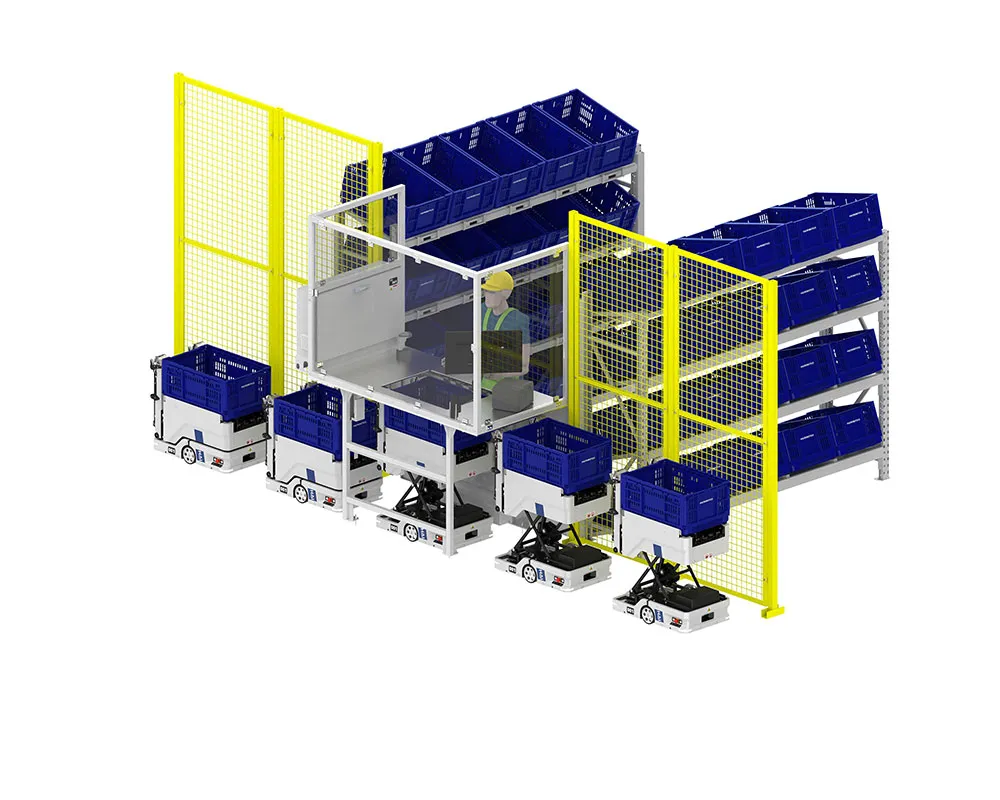

Compact workstations feature an intuitive interface that provides clear instructions for operators to use easily, ensuring faster training and consistent performance, resulting in higher picking accuracy and customer satisfaction.

Simple implementation makes scaling child’s play. Add more robots to the system to increase efficiency, add racks for extra storage, or expand capacity with additional system components. Start small with low upfront costs and scale your system as your business grows without any operational interruptions.

HaiClimber Robots

With a design philosophy that values both simplicity and efficiency, HaiClimbers are masterfully designed to simplify inventory automation, eliminate limitations of legacy technologies, and provide extreme yield density.

Workstations

HaiPick Climb workstations are compact, allowing for more storage and space utilization in your warehouse. Their ergonomic designs and intuitive interfaces ensure fast and accurate picking with 99%+ picking accuracy, requiring no human circulation to fulfill each order. These workstations provide 4 times the operational efficiency and 3 times more daily work volume compared to manual-dependent operations, helping to overcome challenges from labor shortages and increasing employee productivity while reducing laborious tasks.

ILA IWS Software

With a design philosophy that values both simplicity and efficiency, HaiClimbers are masterfully designed to simplify inventory automation, eliminate limitations of legacy technologies, and provide extreme yield density.

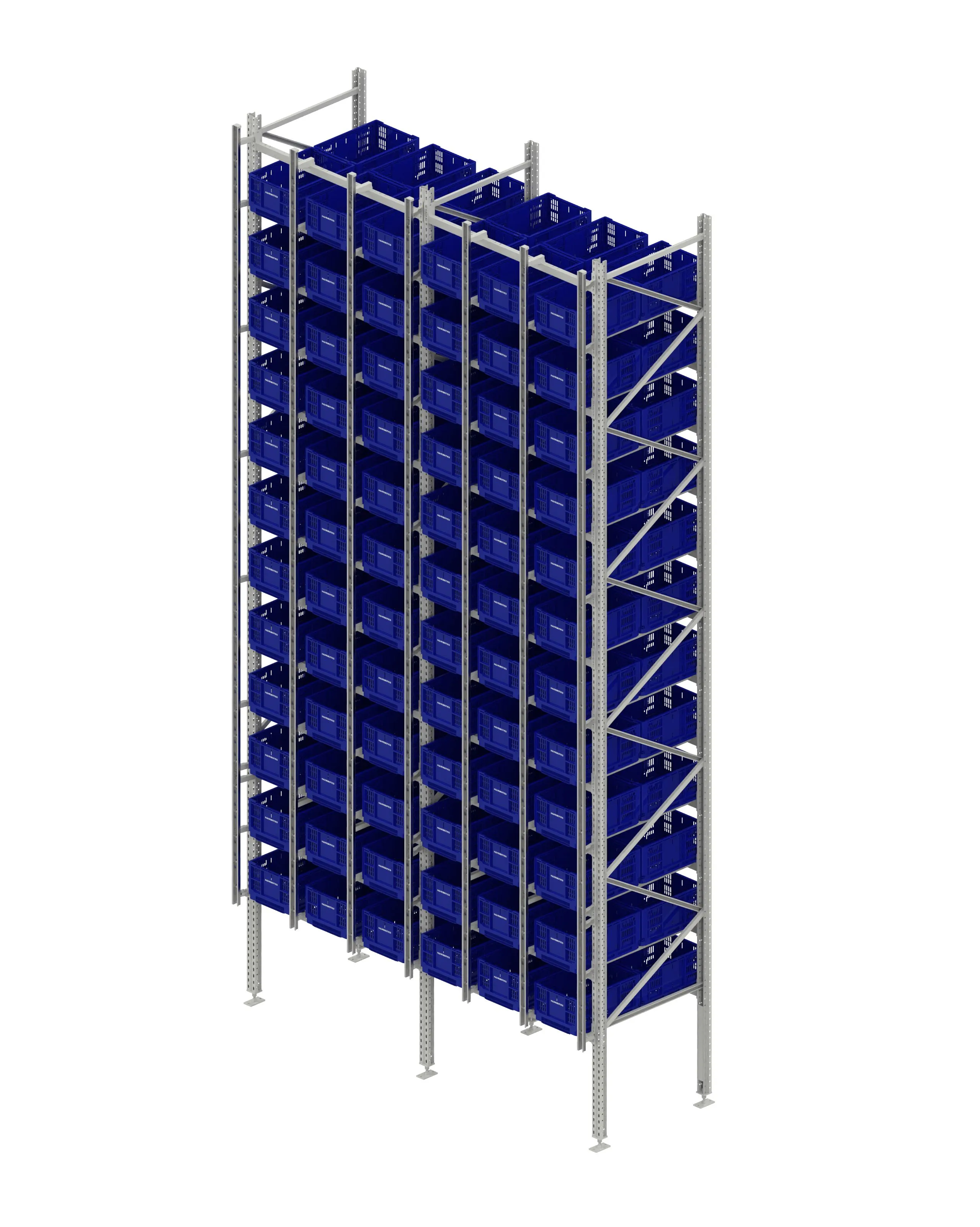

Racks and Plastic Totes

HaiPick Climb can be implemented with most standard cross-braced racking up to 12 meters in height, and guide rails can be attached to one side of the racking to assist robots in their ascent. The racks can be installed with narrow aisles up to 900 mm wide for maximum storage density.

Are You Ready for Transformation in Your Warehouse?

Contact us to take your warehouse operations to the next level.